Ferro-alloys.com: The 17th China Ferro-alloys International Conference, co-sponsored by China Chamber of Commerce of Metals, Minerals & Chemicals Importers & Exporters (CCCMC) and Ferro-alloys.com and co-organized by Chongqing Bosai Group is held in Chongqing on September 23-25, 2020.

Chongqing Bosai Mining (Group) Co., Ltd. (abbreviated as "Bosai Group") was founded in August 1994, with total assets of over 12 billion yuan, annual sales of 30 billion yuan, and more than 7,500 employees worldwide, including 1,200 foreign employees. There are more than 12 large-scale production enterprises and branches in Chongqing, Sichuan, Inner Mongolia, Germany, Guyana in South America, and Ghana in Africa. It is one of the earliest and most successful companies in Chongqing and even China to "go global".

At present, Bosai Group has more than 300 million tons of high-quality bauxite and more than 30 million tons of high-grade manganese ore in the world, and has always adhered to the development direction of two major products of aluminum and manganese. Bosai series products sell well in more than 30 countries around the world, as well as the vast domestic markets. Among them, the production and sales of high-aluminum clinker and brown fused alumina rank first in the world. In various authoritative rankings of the country and Chongqing City, Bosai Group has been ranked among the top 500 Chinese private enterprises, the top 500 Chinese manufacturing companies, the top 50 Chinese non-ferrous metal industrial enterprises, and the top 10 private enterprises in Chongqing for many years.

Director Zhang Duping of Ulanqab Ferroalloy Industry Association served as the chairperson of the meeting

Opening speech

At the beginning of the meeting, Jiang Hui from CCCMC, Fan Yuqing, Deputy General Manager of Bosai Group, the co-organizer, and Mr. Liu Zhengzhi, Chairman of the organizer, China Ferro-alloys.com, delivered opening speeches to the representatives of all parties who came to the meeting and expressed a warm welcome and heartfelt thanks with the great wish for a complete successful meeting.

Speech by Jiang Hui from CCCMC

Speech by Fan Yuqing from Bosai Group

Welcome speech by Liu Zhengzhi from China Ferro-alloys.com

Scene of the meeting

Keynote speech

High Quality industrial Development in the 14th five years: Problems and countermeasures

Lu Tie, researcher, Institute of Industrial Economics, Chinese Academy of Social Sciences

Mr. Lu pointed out that high-quality development is a dynamic concept, which refers to a desirable economic development method that adapts to the changing requirements of the economic development stage, can effectively solve the outstanding problems faced in the new stage, and better achieve the development goals of the new stage. To promote the realization of high-quality development in our country, we need to deal with five aspects: the relationship between supply and demand; the relationship between input and output; the relationship between government and the market; the relationship between fairness and efficiency and the relationship between domestic and foreign countries. The status and role of industry in the national economy are still important, but the way in which it functions has changed. In the past, it was mainly through scale expansion to promote economic growth. The new stage will mainly use its own efficiency improvement and create demand for the development of producer services to promote high-quality economic development.

Mr. Lu further pointed out that the labor productivity, R&D input and output intensity of China's manufacturing industry lag behind the global manufacturing powers, and energy efficiency has not formed a global competitive advantage. At present, China's manufacturing industry is increasingly squeezed by both ends of the industrial chain in the global market, and the traditional scale advantage is accelerating attenuation, and the quality and benefit advantage has not yet formed in the global manufacturing structure. To promote the high-quality development of our country’s industry, three things need to be done: strict protection of consumer rights; effective protection of intellectual property rights and a complete corporate credit system.

Current situation and development of Ferroalloy industry in China

Shi Wanli, secretary general of China Ferroalloy Industry Association

Mr. Shi said that during the epidemic, the alloy industry was constrained by factors such as phased transportation restrictions, lower operating rates in downstream industries, rising production costs, and chaotic market order. However, with the joint efforts of key manufacturers in the industry, it has been achieved. The smooth operation ensures the alloy demand of the downstream industries dominated by steel mills. The effective prevention and control of the domestic epidemic, the timely adjustment of macroeconomic policies, and the rapid pull of the follow-up economic "inner cycle" have laid the foundation for the subsequent promotion and improvement of the alloy industry. At present, the alloy industry still has overcapacity and overproduction, obvious regional differentiation, coexistence of new and old capacity, and chaotic market order, and other pressures. Strengthening industry self-discipline, strengthening communication, strengthening operation quality improvement, and strengthening collaboration are still difficulties for the industry to overcome The foundation and guarantee.

The overall operation situation of China's steel industry in 2020-2023

Li Chuang, chief designer of metallurgical Industry Planning and Research Institute

Mr. Li said that whether the production capacity is excessive depends mainly on whether the operating efficiency can be stable for a long time. At present, the supply capacity of our country's iron and steel industry continues to grow, and cost reduction and efficiency enhancement of iron and steel enterprises are the eternal theme. "From steel to materials, from manufacturing to service, from China to the world, from a single company to an ecosystem of the entire industrial chain" is an inevitable trend for the development of steel companies. The ultimate increase in competitiveness is essential for the survival and development of steel enterprises.

Product and technological innovation is the foundation for steel companies to settle down.

The industrial chain and ecosystem are the foundation for steel companies to win competition.

Mr. Li believes that as China’s economy shifts from a high-speed growth stage to a high-quality development stage, the role of consumption in driving economic growth has gradually emerged. The situation of economic growth over-reliance on investment will change. Fixed asset investment will remain at a relatively low speed. Consumption intensity further declines (in 2019, China’s per capita apparent steel consumption reached a new high, breaking 600kg to 632.9kg, a sharp increase of 44.4% compared to 2010, second only to South Korea and Taiwan, and ranking third in the world. 2.76 times the world average), steel production and consumption will generally show a downward trend, entering a stage of reduction development. During the "14th Five-Year Plan" period, with the adjustment of the layout of "light investment, heavy consumption" in the domestic economic restructuring and transformation, and the continuous increase in the proportion of the tertiary industry and strategic emerging industries, it is in line with the strategic emerging industries and high-end manufacturing industries. Some related special steel products will continue to grow. The demand for section steel, special steel bar and wire rod, hot-rolled sheet and strip, and electrical steel sheet and strip continued to grow, while the demand for construction steel bars, coils, and hot-rolled narrow strip steel declined.

Discussion on the latest ecology and trend of stainless steel industry

Senior expert in stainless steel industry

Experts said that from the perspective of the cumulative supply and demand of stainless steel, it has been basically the same year-on-year, which is also effectively verified by the fact that the overall market inventory is basically close to the same period. Considering that the current raw materials are still strong, profits are almost exhausted, steel mills continue to hold up prices, and the short-term spot market is unlikely to fall sharply. The small peak of pre-holiday stocking will soon be ushered in. Faced with today's abundant inventory and a large amount of arrival pressure, the market will choose to ship as soon as possible to digest the inventory. The trend of the stainless steel market is expected to be dominated by weak shocks.

The stainless steel industry has shown a rebound in supply and demand under the epidemic; the peak season is not prosperous, and the off-season is not short; downstream industries are upgraded; downstream products have realized the four characteristics of replacing overseas production. Stainless steel crude steel production capacity has once again ushered in rapid growth. Steel mills strengthen channel management and control to reduce invalid circulation. The Yangjiang intermediate frequency furnace started to be demolished, and the tool steel industry ushered in an upgrade. The European Union, South Korea and other anti-dumping measures against Chinese stainless steel have restrained Chinese stainless steel exports.

Since the listing of stainless steel futures on September 25, 2019, it has brought more possibilities to entities. In the future, with the launch of chromium futures, the futures and spot integration of nickel-chromium stainless steel will be more interactive and in-depth, which is bound to bring more unlimited possibilities to the development of the nickel-chromium stainless steel industry chain.

Global manganese ore pattern and supply and demand situation

China ferro-alloys.com analyst Tian Yawei

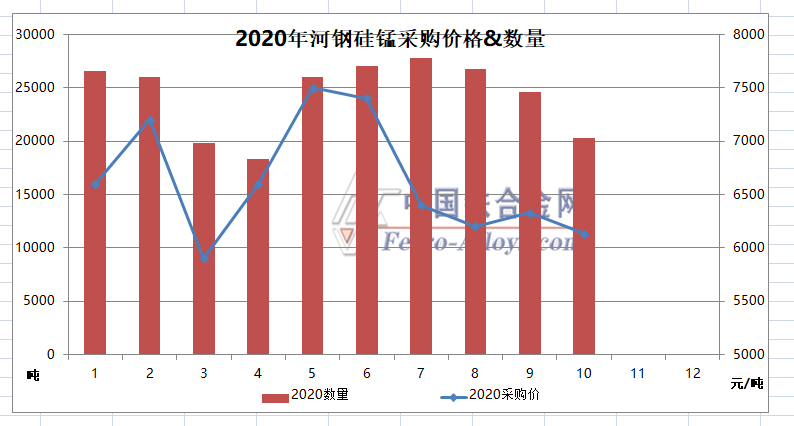

Mr. Tian said that from the perspective of large-scale steel group purchases, the average monthly purchases as of September 2020 has declined compared with the same period last year. Silicomanganese companies are facing a situation of weakening demand, while silicomanganese production capacity has increased, but domestic crude steel production remains high. Create a new high. Since 2019, new silico-manganese production capacity has been put into operation, monthly output has gradually increased, the supply of silico-manganese continues to increase, domestic port manganese ore inventory continues to increase, silico-manganese market prices are sluggish, some power cuts in Inner Mongolia, manufacturers have adopted production reduction measures to ease full-load production situation. In terms of manganese ore, the import volume of manganese ore reached a record high of nearly 34 million tons in 2019. Since 2019, domestic manganese ore inventories have continued to increase to 5-6 million tons. Under the influence of the epidemic, the monthly manganese ore imports have declined year-on-year. The average appreciation will affect the prices of futures mines and port mines. The manganese ore market is also affected by spot inventories, demand, and silicomanganese prices. In terms of futures, the impact of futures on spot alloy prices has increased. During the outbreak in South Africa, the 05 contract can be seen to perform rapidly. Futures have driven the increase in spot prices, and indirectly affected the monthly purchase prices of steel companies. The price of manganese ore also increased substantially.

The importance of port logistics service in mining supply chain

Li Youfu, President of Tianjin Telenda International Freight Forwarding Co., LTD

Tianjin Telenda International Freight Forwarding Co., Ltd. is a comprehensive and professional modern international freight forwarding logistics company. The company relies on Tianjin Port, radiates North China, Northwest, Northeast and other regions of the country, and has established branches and offices in Jingtang Port, Caofeidian and Dalian. The company has been engaged in freight forwarding and warehousing services for the import and export of containers and bulk cargo for many years.

Chairman Li Youfu said that in the future, Telenda would always adhere to the concept of serving customers wholeheartedly, so that customers could be assured and satisfied; be responsible for the company; sincerely help customers solve various problems in the logistics process and propose solutions; focus Feedback and communication with customers’ reasonable requirements; strengthen internal management and continuously improve and perfect the company’s business processes; train and cultivate the concept of customer service and implement them to the grassroots and on-site; carefully accept customer criticism and guidance, actively correct shortcomings and concentrate Fully provide customers with industrial chain logistics services, ensure the safety of goods, live up to the trust of customers, turn trust into practical actions, improve cultural value and service quality, and develop positively and steadily.

How to innovate the traditional supply and marketing mode of ferroalloy

Li Juan, senior analyst of Huarong Rongda Futures

Ms. Li said that the traditional supply and marketing model of ferroalloys cannot truly reflect the relationship between supply and demand in the market, and lacks continuity, stability and certainty; new trade models (futures and options, etc.) can help solve the problems of insufficient research and information asymmetry in the traditional industry chain. Provide capital services and pallet business for downstream, conduct industrial research and provide information services for the industrial chain.

Regarding the principle, definition, purpose and case of hedging, the logic of basis trading and weighted trade, wind direction management, operation mode, etc., Ms. Li gave a detailed explanation and introduction at the meeting.

How do traders survive in metallurgical supply chain

Wang Huiying, General Manager of Beijing Longyue Mining Co., LTD

Enterprises must implement the "contract-honoring and credibility" in order to seize opportunities and establish long-term cooperative relationships, Ms. Wang Huiying emphasized in her speech. The metallurgical supply chain is interlinked. Enterprises should recognize their position, understand and study each link and industry development trends, look for opportunities, and understand the difference between the supply side and the sales side, and adapt to local conditions.

At the same time, Ms. Wang said that the company should change from a trade concept to a service concept, and at the same time, it should pay attention to the team spirit and establish the "squad octopus spirit" to make the company invincible.

Brief introduction of domestic ferrosilicon market from January to September 2020

China Ferro-alloys.com analyst

The steel market performed strongly in August, and the "Golden September and Silver October" was ushered in a good start. However, the terminal demand did not meet expectations and the market is in a downward trend. There is still room for improvement in the relationship between supply and demand. Factors such as the introduction of environmental protection production restriction policies and capacity replacement inspections in many places have brought certain restraints on the supply side. It is expected that the growth rate of steel production in the fourth quarter will slow down, and the actual consumption side will enter a stable period. The steel market may fluctuate in the short term Consolidation is the main focus; the production situation of magnesium metal is stable, the downstream demand is weak, the export market is sluggish, the oversupply pattern dominates the market trend, the manufacturer's inventory is accumulated, and the price continues to fall under pressure, which will not benefit much in the short term. At present, the ferrosilicon export market is sluggish, the spot is tight, and manufacturers have no inventory pressure for the time being, and they have placed orders for production; the prices of raw materials such as silica and blue carbon are rising, and the demand from downstream steel mills is relatively stable, but the futures disk is weak and the delivery warehouse inventory is relatively high. Under the environment, it is expected to operate stably in the short term.

Group photo

Business negotiation & corporate display

.jpg)

.jpg)

.jpg)

This conference is supported by the Ferroalloy Industry Association. About 200 people from 37 major manganese companies and 15 steel companies attended the conference. This meeting is a very important ferroalloy meeting before the holiday, and it is an important meeting that provides information exchange and business cooperation for participants.

- [Editor:zhaozihao]

Save

Save Print

Print Daily News

Daily News Research

Research Magazine

Magazine Company Database

Company Database Customized Database

Customized Database Conferences

Conferences Advertisement

Advertisement Trade

Trade

Tell Us What You Think