Over the 2010s, there have been two high to low price cycles, with the start of 2020s already kicking off with the next one. The first high of the 2010s followed the strong recovery in 2010 and 2011 after the global financial crisis, with European high-carbon ferrochrome prices plateauing at around US$1.3/lb Cr, before following a steady decline to bottom out at around US$0.8/lb Cr in H1 2016. The second cycle followed a surge in demand from Chinese stainless steel producers in end-2016 and 2017 that maintained a second phase of high prices (with volatility) through to mid-2018 at a similar high of over US$1.3/lb Cr, before again falling to the similar US$0.8/lb Cr floor in H2 2019 and into Q1 2020. As of Q2 2021, European ferrochrome prices have once again returned to above the US$1.3/lb Cr level following a rapid increase in the first quarter of the year.

Roskill View

Downstream, it is the stainless steel industry that determines the demand for high-carbon ferrochrome. Ferrochrome prices are influenced by supply and demand factors in the short term but, like most other bulk ferroalloys, are primarily cost-driven in the longer term, broadly following similar trends to chromite ore prices. The main reason for this is that chromite is the largest cost component in ferrochrome production, and China (the largest ferrochrome producing country) buys and imports all its chromite on the open market. Overall the trends in ore prices have tracked the 90th percentile of the industry cash costs; however, since the price low of 2016, supply and demand dynamics exerted an added impact on price trends above and below the long-term cost controls. While costs increased in end-2016, it was high demand from Chinese stainless steel and in turn ferrochrome that supported the surge in ore prices over 2017 and into 2018. High prices incentivised production, which shifted the market into a structural surplus as demand growth slowed again in H2 2018 and weakened in 2019 with prices falling well below the industry cost base by the end of the year. The onset of the COVID-19 pandemic saw production costs for chromium ores decline, which provided a lifeline for struggling producers at the time.

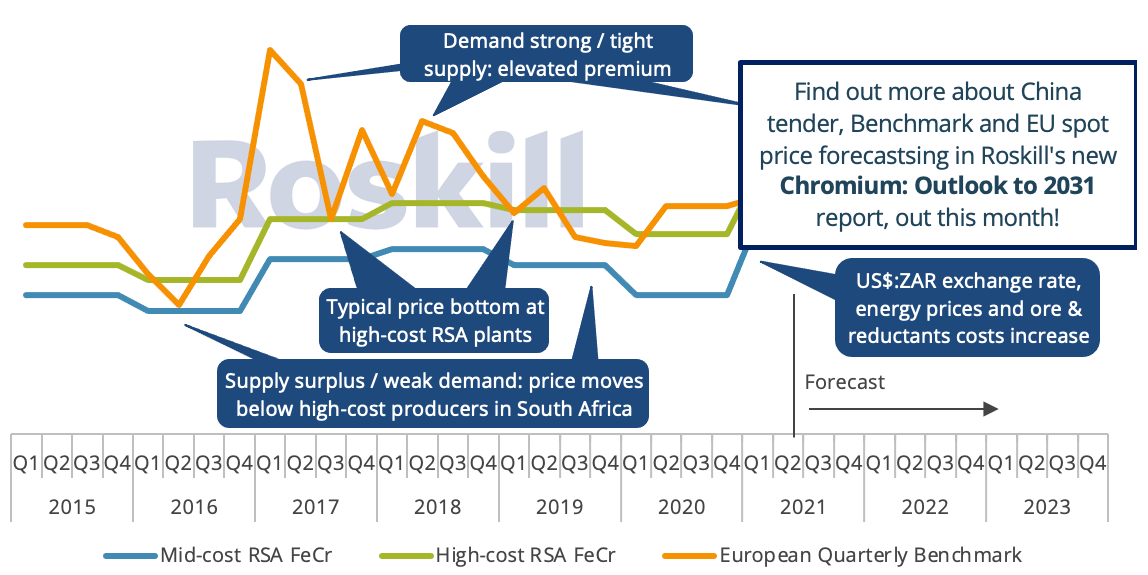

A similar narrative to ores, as outlined above, underpins the ferrochrome industry. However, the ore supply market remains dominated by South Africa and cost of mining in the country, whereas South Africa has lost its dominance in the ferrochrome industry. There are two key price publications for ferrochrome that guide industry prices: The European Quarterly Benchmark price published by Glencore-Merafe in South Africa and the Chinese ferrochrome tender price published by the major stainless steel mills in China.

The quarterly benchmark prices are used in Europe as an input to calculate the alloy surcharge for stainless steel prices. The true spot price in Europe tends to fluctuate between the Benchmark price, a discount set by the market conditions at the time and the trends of the Chinese ferrochrome tender price, which is adjusted monthly. The Benchmark price is set by South African ferrochrome producers, which used to be the largest source of ferrochrome, before China advanced to that position in 2012. South African ferrochrome remains a key source of ferrochrome outside of China and, as such, it is the cost of ferrochrome production in South Africa that underpins the lower limits to Benchmark prices. While the highest cost producers in South Africa typically represent the downward barrier to Benchmark prices, periods of more significant oversupply (such as H1 2016 and H2 2019) have seen the Benchmark base set by South Africa’s mid-cost plants. In these times, the highest cost producers become uneconomical and at risk of closure. As with ores, in times of tighter supply the Benchmark tracks a healthy premium above the highest cost South African producers, as was the case over the 2017-2018 demand surge and is the case again in Q2 2021.

China has continued to increase its dominance in the ferrochrome industry since 2012, while South African ferrochrome producers face ongoing headwinds from lack of reliable energy supply and rising electricity tariffs. Unlike the Benchmark price, the Chinese ferrochrome tender price fluctuates between China’s lowest cost producers (in Inner Mongolia) and China’s highest cost producers (in southern China). With Inner Mongolia representing the largest ferrochrome hub in China and the location of ongoing capacity investments, the lower cost Chinese operations have taken a growing role in setting the price trends with the market healthily supplied. The downward pressure on prices from supply growth in Inner Mongolia has seen the premium of the European Benchmark widen considerably over the last decade and more. With the Chinese tender price declining month-on-month since March 2021, the question remains as to what the Benchmark level will be for the third quarter and beyond.

There have been several coinciding trends that underpin the fundamentals of the ferrochrome industry and its price and with four of the following key points. (1) Demand recovery is already well on its way, following the worst of the COVID-19 impacts, with record stainless steel levels in China supporting growth to record demand in 2021. (2) In end-2020 and Q1 2021, demand was exaggerated by restocking of low inventories at smelters and stainless steel mills. (3) Ferrochrome production costs have surged in 2021 with the rise in oil, energy and reductants costs as well as surging freight rates impacting the cost of ores to reach Chinese ferrochrome furnaces. (4) Inner Mongolia’s government has initiated the closure of smaller less efficient furnaces as part of China’s 14th 5-Year Plan targeting high-energy consuming industries.

South African ferrochrome supply has benefitted from the recent events in China, which has removed significant capacity through the closure of small furnaces. While higher cost furnaces in southern China have been able to fill the short-term gap, the demand expectations will require South African plants to remain operational over 2021. As such, Roskill predicts that the Q3 and Q4 2021 Benchmark price will maintain a premium to the South African cost structure, but following the downward trend set by the Chinese stainless steel mills (as is usually the case). In the medium-term, beyond 2021, the requirement of South African ferrochrome capacity to operate at its current high utilisation rate remains at a tipping point, especially with new ferrochrome capacity already under construction elsewhere to meet rising demand. Therefore, unless South African ferrochrome furnaces regain competitive advantage, the Benchmark will likely drop below the higher cost producers as supply tightness is relieved.

Source: Roskill

Copyright © 2013 Ferro-Alloys.Com. All Rights Reserved. Without permission, any unit and individual shall not copy or reprint!

- [Editor:kangmingfei]

Save

Save Print

Print Daily News

Daily News Research

Research Magazine

Magazine Company Database

Company Database Customized Database

Customized Database Conferences

Conferences Advertisement

Advertisement Trade

Trade

Tell Us What You Think